The first practical step for this process was to attempt to understand the form of the topiary as best as possible, as a sort of visual analytical process. Although the plant itself has lots of smaller elements and irregularities within its shape, the overall form of the plant is an elegant spiral set upon a traditional terracotta pot, which in itself has quite a pleasant form ideal for the level of metal working required for this project

|

| This quick sketch is part of my visual analysis of the shape and form of the spiral |

|

| These sketches look at the shape and form of the terracotta pot at the base of the plant |

Although simple, these quick sketches helped myself gain a better understanding of the shapes within the object. My analysis suggested that although the spiral is the most evident part of the object, that the pot maybe the most practical form for the later stages of this project. I would suggest that anyone looking at choosing an object for this first part of the process to undergo a series of visual analysis in their own style, in an attempt to gain a greater understanding of the forms involved within their shape. Sometimes there is a lot more to an object than you initially think and a visual analysis can help reveal them.

The next step of this process was to capture the required images of my object using the 123D Catch phone application and produce an accurate three dimensional model. The application is quite self explanatory and has a usable interface that indicates what images need to be captured and in what sequence. It also offers up a series of instructions and suggestions before you begin.

These images are examples of the guidance and instruction that the app will provide before beginning the process

Once the images have been taken, press the tick in the top right hand corner and the following images will appear as the next three stages, follow the instructions as the application prepares to render the 3D model:

After the application has finished producing a render of the object, it can be viewed and analysed within the phone app. Once i decided that i was happy with the result, the next step was to login to my Autodesk account on my laptop and review and edit the model.

The next stage is Meshmixer, a program i had never heard of, let alone had any experience with, none the less i found it extremely simple and beneficial for simplifying the form of the object. I would suggest that for anyone about to use the program for the first time to watch a series of tutorial videos online before attempting it themselves.

Being able to simplify the form of the topiary definitely helps a lot in the next stage of the process. By smoothing the surfaces and imperfections in the object 123D make is able to process and model a lot quicker and without any major problems.

I then saved the Meshmixer file as a OBJ and exported it into 123D Make

123D Make:

It is extremely important to follow these steps as the laser cutter can only interpret red and blue lines in RBG colour mode

Red indicates a full depth cut and Blue indicates and scolding cut

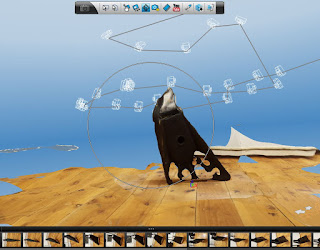

After 123D Catch had generated a 3D model of the Spiral

Topiary, I used the Lasso selection tool to edit out the background and all the

unwanted parts of the 3D Image. I attempted to give it the simplest form

possible, so that 123D Make would have an easier time processing the model.

Once i was satisfied with the result i saved the file as an STl and exported it into Meshmixer.The next stage is Meshmixer, a program i had never heard of, let alone had any experience with, none the less i found it extremely simple and beneficial for simplifying the form of the object. I would suggest that for anyone about to use the program for the first time to watch a series of tutorial videos online before attempting it themselves.

Being able to simplify the form of the topiary definitely helps a lot in the next stage of the process. By smoothing the surfaces and imperfections in the object 123D make is able to process and model a lot quicker and without any major problems.

I then saved the Meshmixer file as a OBJ and exported it into 123D Make

123D Make:

The following images are the different options that 123D

Make offers when it comes to printing and laser cutting layouts. I ended up

choosing the stacked slices option (shown above) as it provided the strongest form and it was

much more aesthetically pleasing. Although it would take a lot longer to

produce and cost a decent amount more in materials. I also recommend this option for the later stages of the project, the stronger the model is the easier it will be to shape the metal skin around it.

These images demonstrate the other options within 123D Make.

The next step is to adjust the sheet layout in 123D Make for the laser print. The 123D Make program allows you to organise the layout of your sheet including, sheet sizes, width and general layout in regards to material optimisation (reducing wastage)

From the 123D Make computer program i saved the

printing layout as a PDF. Before you do that, you must set the parameters for the printing file, as this cannot be done during later stages.

I used 6 x 2mm Matte board with a sheet size of 600mm x

300mm, which i purchased from the square house shopfront.

The 123D Make program produced 175 individual layers for my

model, at this scale.

The Dimensions of my Model, after being scaled down in

Meshmixer and Make is 350mm in height with a 106mm diameter at the base of the

pot. The diameter of the object varies as the spiral extends upward.

These PDFs will then be opened in illustrator and edited according to cutting depth and width.

The next step is to open each individual sheet as a PDF in Adobe illustrator, the reason for using Illustrator is that produces an Ai. file which can be interpreted by the laser cutter and printed.

The following steps need to be followed precisly as the laser cutter has specific settings to adhere to:

1. The colour mode needs to be in RBG. Select FILE>DOCUMENT COLOR MODE>RBG COLOR

2. Select ANY BLUE LINE>SAME>STROKE COLOR

3. Change the line weight to 0.001mm and set the colour to:

4. Select ANY RED LINE>SAME>STROKE COLOR

5. Change the line weight to 0.001mm and set the colour to:

It is extremely important to follow these steps as the laser cutter can only interpret red and blue lines in RBG colour mode

Red indicates a full depth cut and Blue indicates and scolding cut

Once these steps have been done for each page they can be sent, one at a time through to the laser cutter which runs through its own program.

It is best to complete these final Adobe Illustrator steps on the laser cutting computer as the files can be sent straight from Illustrator to the laser cutting program

6. Select FILE>PRINT

The file will then automatically open and the next stage will begin.